28kHz Ultrasonic Handheld Plastic Spot Welder for Plastic Hardware

Package Size 30.00cm * 5.00cm * 15.00cm Package Gross Weight 6.000kg 28khz Ultrasonic Handheld Plastic Spot Welder for P

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | RPS-WC28 |

| Frequency Range | Low Frequency |

| Electric Current | AC |

| Style | Handheld |

| Power | Ultrasonic |

| Vibration Method | Self-Extraction |

| Product Size | 20mm*5mm |

| Horn | Grid Horn |

| Welding Time | 0.01-9.99sec |

| Horn Material | Titanium, Alumnium Alloy |

| Horn Size | Customized |

| Frequency | 28kHz |

| Transport Package | Carton |

| Specification | 45*27*25cm |

| Trademark | Rps-sonic |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200PCS/Month |

Packaging & Delivery

Package Size 30.00cm * 5.00cm * 15.00cm Package Gross Weight 6.000kgProduct Description

28khz Ultrasonic Handheld Plastic Spot Welder for Plastic Hardware

| Basic Info. | |

| Model NO. | RPS-SW28 |

| Frequency | 28kHz |

| Horn | 20mm*5mm |

| Horn Material | Alumium Alloy or Titanium Alloy |

| Generator | Digital Generator |

| Weight | 5kg in Totall |

| Transport Package | Carton |

| Specification | 45*27*25cm |

| Trademark | Rps-sonic |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200PCS/Month |

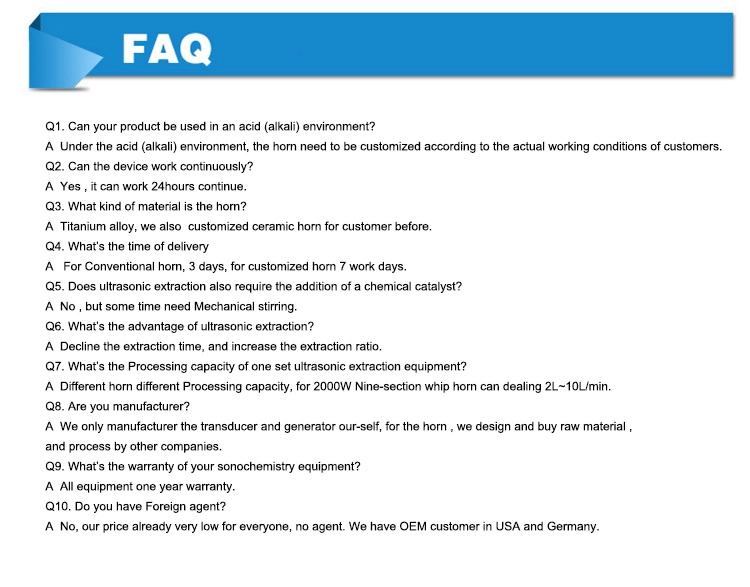

Introduction:

Ultrasonic spot welding machines are widely used in the plastic industry around the world. The working principle of ultrasonic spot welding machines is to use the high-voltage and high-frequency signals generated by the generator to convert them into high-frequency vibration through the energy conversion system and add them to plastic products. On the surface, the friction between the workpiece surface and the internal molecules is generated by vibration at the interface. When the temperature reaches the melting point of the workpiece, the workpiece interface rapidly melts, then fills the gap between the interfaces. After the vibration stops, the workpiece is cooled and formed under a certain pressure To achieve perfect welding. Ultrasonic welding is an advanced process for joining plastic parts due to its fast, clean, and safe advantages. This technology can replace the solvents, adhesives, studs or other mechanical fixing methods used in the past. Applying this technology can improve production efficiency ,lower the cost.

Application of ultrasonic spot welding machine:

For decoration, ribbon spot welding, riveting, etc., portable spot welding machines are widely used in the clothing industry, trademark industry, automotive industry, plastic electronics, household goods industry, etc. Simple operation, high price and practical advantages.

Apparel industry: sewing process of underwear and underwear, welding of webbing elastic band, etc .; can be used for spot drilling.

Trademark industry: woven ribbons, printed ribbons, etc.

Automotive industry: door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.

Plastic electronics: small plastic parts riveting, etc.

Houseware industry: fiber cotton spot welding and so on.

Advantages:

1. High stability: The digital electric box automatically tracks the resonance frequency and adjusts the output frequency to match the handheld device. Once a fault is found, the work stops and the alarm is issued, and most of the ultrasonic welding can be completed within 0.1-0.5 seconds.

2.Energy saving and environmental protection: the welding surface is not damaged and deformed, no scratches and glue residues, no need to use a large number of fixtures, flux, glue, reduce labor and reduce costs.

3. Reliable quality: solidified by ultrasonic welding, recombination between molecules to form a strong molecular chain, the strength of the weld can be close to the strength of the raw material, good air tightness, no water leakage, and no air permeability.

4. Simple operation: Ultrasonic welding is very easy to automate. As long as the welding parameters are set, welding can be performed without pre-heating and cleaning.

5.Wide range of applications: Handheld ultrasonic spot welders can be used for welding, riveting, spot welding of films, cloths, and thermoplastic products, as well as inlaying and blanking processes between metal and plastic parts.

Features of Ultrasonic Spot Welder:

1. High-quality imported ultrasonic transducer with strong power and good stability.

2. The whole machine is exquisite in design, small in size and does not take up space. The operation is simple, convenient and practical.

3.800W is more powerful and more powerful than ordinary other products.

4. Assembly of high-quality imported parts of main parts.

5. The noise is slight and the working environment is environmentally friendly.

| Item | Parameter | Advantage: | Application |

28Khz ultrasonic hand welder Straight type | ▪ 28Khz 800W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it'd using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. |

28Khz ultrasonic hand welder Gun type | |||

35Khz ultrasonic hand welder Straight type | ▪ 35Khz 500W ▪ Digital generator ▪ Horn customized ▪ Aluminum alloy&Steel & Titanium alloy ▪ Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max. Straight type suit for both hand /machine operate. Gun type suit for hand operate. | |

35Khz ultrasonic hand welder Gun type | |||

For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Related Products